Inquiry

Form loading...

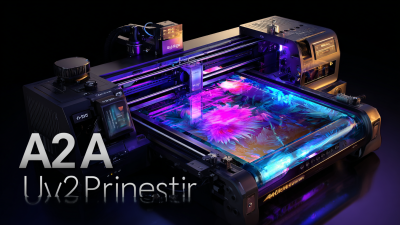

In the ever-evolving world of digital printing, the A2 UV printer stands out as a versatile and powerful tool for achieving exceptional results across various applications. Whether you’re a seasoned professional or a newcomer to the printing industry, harnessing the full potential of your A2 UV printer can significantly enhance your productivity and creative output. This guide presents five essential tips that will help you optimize your printing processes, improve the quality of your prints, and ultimately elevate your business.

From understanding the unique capabilities of your A2 UV printer to mastering the right setup and maintenance practices, these insights will enable you to unlock the true power of digital printing, ensuring outstanding results with every project. Embrace these strategies and watch your printing capabilities soar as you leverage the cutting-edge technology of your A2 UV printer.

When it comes to enhancing your digital printing capabilities, understanding the key features and advantages of the A2 UV printer is crucial. This versatile equipment stands out for its ability to print on a wide range of materials, including plastics, wood, metal, and glass. The LED UV technology ensures quick drying times and vibrant colors, allowing for immediate handling and impressive results. One of the most significant advantages is the durability of the prints, making them suitable for both indoor and outdoor use.

To fully leverage your A2 UV printer's potential, consider the first tip: optimizing your design files. Use high-resolution images and vector graphics to ensure clarity and detail in your prints. Secondly, take advantage of the printer’s diverse media options. Experiment with different substrates to discover what works best for your specific projects. Lastly, regularly maintain your printer by cleaning the printheads and checking ink levels, which will help keep your machine running smoothly and extend its lifespan. By following these tips, you'll enhance your printing experience and achieve outstanding results with your A2 UV printer.

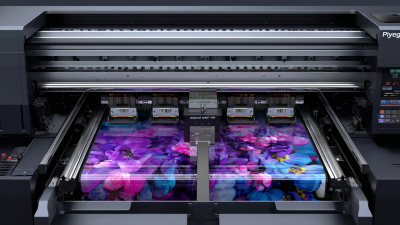

Optimizing your A2 UV printer settings for various materials and designs is crucial to achieving the best print quality. According to the 2022 Smithers report, the UV printing market is expected to grow at an annual rate of 8.5%, emphasizing the importance of mastery in this technology. Different substrates, such as wood, glass, and fabric, require tailored settings to ensure optimal adhesion and image clarity. For instance, adjusting the curing time based on material thickness can prevent issues like warping, which is particularly significant for flexible materials.

One essential tip is to always perform a test print before executing a larger job. This practice allows you to fine-tune your printer's saturation levels and resolution settings according to the specific characteristics of the material. For example, while printing on glossy surfaces, lowering the ink density can help achieve a vibrant finish without risking bleed. Additionally, consider using appropriate pre-treatment solutions, especially with porous materials, to enhance ink adhesion and durability, which can extend the lifespan of your printed graphics significantly.

Another important aspect is the management of the printer's environment. Dust and temperature fluctuations can adversely affect the print quality. Maintaining a clean workspace and ensuring that the printer operates in a stable temperature range of 20-25°C can lead to improved performance. As you continue to explore the capabilities of your A2 UV printer, remember that a keen understanding of material properties and optimal settings will enable you to unleash its full potential.

| Material Type | Optimal Resolution (dpi) | Ink Usage (% for Full Print) | Print Speed (m²/h) | Recommended Coating |

|---|---|---|---|---|

| Plastic | 1200 | 80 | 15 | Glossy Finish |

| Wood | 600 | 70 | 10 | Matte Varnish |

| Metal | 1200 | 90 | 12 | Protective Spray |

| Canvas | 300 | 60 | 8 | Matte Finish |

| Glass | 1200 | 85 | 6 | Glossy Coating |

To ensure the longevity and performance of your A2 UV printer, regular maintenance is vital. According to a report by Smithers Pira, the digital printing market is projected to reach over over $200 billion by 2026, emphasizing the importance of high-quality equipment and consistent upkeep. By following essential maintenance tips, users can not only enhance the performance of their printers but also reduce downtime, which can be a significant cost factor in production.

Firstly, clean the printer’s components regularly to prevent dust and debris buildup that can hinder print quality. This includes the print heads, as clogged nozzles can lead to wasted materials and time. Research indicates that properly maintained printers can achieve up to 30% higher efficiency compared to those that are neglected. Additionally, regularly updating the printer’s firmware can enhance performance and fix bugs that may affect operation, ensuring your A2 UV printer remains at the forefront of digital printing technology. Regularly checking the ink levels and replacing ink cartridges timely can also prevent quality degradation and maintain color accuracy. By investing time in maintenance, you can significantly extend the life of your UV printer and maximize its potential in a competitive market.

Firstly, clean the printer’s components regularly to prevent dust and debris buildup that can hinder print quality. This includes the print heads, as clogged nozzles can lead to wasted materials and time. Research indicates that properly maintained printers can achieve up to 30% higher efficiency compared to those that are neglected. Additionally, regularly updating the printer’s firmware can enhance performance and fix bugs that may affect operation, ensuring your A2 UV printer remains at the forefront of digital printing technology. Regularly checking the ink levels and replacing ink cartridges timely can also prevent quality degradation and maintain color accuracy. By investing time in maintenance, you can significantly extend the life of your UV printer and maximize its potential in a competitive market.

A2 UV printing technology is rapidly transforming multiple industries, offering exceptional versatility and efficiency. The unique curing process of UV printing allows for diverse applications, such as promotional materials, signage, and packaging, thereby enhancing visual appeal and durability. Businesses in sectors like automotive, electronics, and healthcare are increasingly adopting A2 UV printers to meet specific requirements, like producing intricate designs and high-quality prints on various substrates.

The ongoing expansion of the global UV printer market, expected to grow from $14.4 billion in 2024 to $19.2 billion by 2033, underscores the significant impact of this technology. Furthermore, the development of UV-curable resins is revolutionizing traditional manufacturing practices, offering a more sustainable and efficient alternative in additive manufacturing. Companies are increasingly recognizing the potential of A2 UV printing in driving innovation and productivity, paving the way for creative applications that push the boundaries of design and manufacturing across various industries.

When it comes to optimizing your A2 UV printer’s potential, an efficient workflow is crucial for digital printing success. Streamlining your processes can save you time and reduce errors, allowing you to take on more projects without sacrificing quality. Start by organizing your workspace to ensure all necessary materials and tools are within reach. This not only enhances productivity but also minimizes the chances of disruptions during the printing process.

Another vital tip is to establish a clear communication channel within your team. Ensuring that everyone understands their roles and responsibilities can prevent bottlenecks and misunderstandings. Implementing a project management tool can aid in tracking progress and deadlines, keeping your team aligned and focused on their tasks.

Finally, consider routinely evaluating your workflow to identify any inefficiencies. By remaining proactive and adaptable, you can continuously refine your processes, ultimately leading to greater output and successful digital printing endeavors.