Inquiry

Form loading...

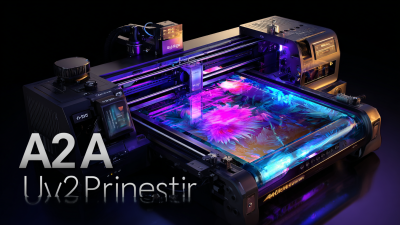

In today's fast-paced manufacturing landscape, maximizing production efficiency is paramount for businesses aiming to stay competitive. The rise of the multifunctional UV printer has revolutionized the printing industry, offering unparalleled versatility and speed. According to recent market reports, the global UV printer market is expected to grow at a CAGR of over 15% by 2025, highlighting the increasing demand for innovative printing solutions. By employing a multifunctional UV printer, companies can streamline their operations, reduce material waste, and expand their service offerings—all while maintaining high-quality output. As industries across the board, from signage to packaging, embrace this technology, understanding how to leverage the capabilities of a multifunctional UV printer can significantly enhance productivity and profitability in your business.

Multifunctional UV printers are revolutionizing production efficiency across various industries by combining multiple printing techniques into a single device. These printers are designed to handle a wide range of materials including coated papers, plastics, and even textiles, allowing businesses to diversify their product offerings. According to recent industry reports, the global UV printer market is expected to reach $3.2 billion by 2025, showcasing the growing demand for multifunctional and versatile printing solutions.

One of the key advantages of multifunctional UV printers is their ability to print in high resolution while maintaining speed, making them suitable for both small and large-scale production. For instance, advancements in UV shielding technologies, powered by materials such as SiO2NP, have significantly enhanced print quality and durability. This innovation not only improves the surface structure and strength of printed products but also provides excellent barrier and UV protection, ensuring longevity and resilience in various applications. The integration of these advanced features underscores the potential of multifunctional UV printers in streamlining workflows and maximizing production efficiency.

In the fast-paced world of printing operations, measuring production efficiency is essential for maximizing output and minimizing costs. Key metrics such as Overall Equipment Effectiveness (OEE), cycle time, and throughput provide invaluable insights into operational performance. According to the Printing Industries of America, the average OEE for printing companies hovers around 60-70%, indicating a significant opportunity for improvement. By leveraging a multifunctional UV printer, businesses can enhance their OEE through improved machine utilization and reduced downtime.

Another critical metric is cycle time, which measures the total time taken to complete a production run. Industry benchmarks suggest that effective cycle time can be reduced by 20-30% with the use of advanced printing technologies. Multifunctional UV printers excel here, as they allow for quick changeovers and the ability to print on various substrates without lengthy setups. Additionally, monitoring throughput—measured in square meters or impressions per hour—can reveal how efficiently resources are being used and highlight potential bottlenecks in the workflow. Implementing these metrics ensures that printing operations are not only efficient but also adaptive to changing market demands.

To optimize workflow with UV printers across various applications, it is essential to implement best practices tailored to your production environment. According to a report by Smithers Pira, the global market for UV printing is projected to grow at a CAGR of 5.3% from 2021 to 2026, highlighting the increasing demand for efficient printing solutions. One of the most effective strategies is to invest in proper training for operators. Research indicates that trained personnel can enhance output quality by up to 30%, significantly reducing waste and rework associated with manual errors.

Moreover, it’s vital to streamline the pre-press and post-press processes. Integrating workflow automation software can cut down production time by almost 20%, allowing for faster job processing and minimizing idle time. Utilizing specialized RIP software that optimizes image processing for UV printing can lead to improved color accuracy and reduced ink consumption. Overall, these adjustments can not only increase the productivity of your multifunctional UV printer but also broaden the range of applications—from signage to packaging—where UV technology can be effectively utilized.

| Application | Recommended Settings | Key Benefits | Common Materials |

|---|---|---|---|

| Signage | High speed, 1200 DPI | Fast production, vibrant colors | PVC, Acrylic, Foam board |

| Packaging | Moderate speed, 600 DPI | Customization, reduces waste | Cardboard, Plastic |

| Decorative Items | Fine detail, 1440 DPI | Artistic effects, high resolution | Wood, Glass, Canvas |

| Textiles | Lower speed, 300 DPI | Soft touch, flexible printing | Cotton, Polyester |

| Industrial Parts | High durability, 1200 DPI | Resistance to wear, long-lasting | Metal, Plastic, Resin |

Multifunctional UV printers have emerged as crucial investments for businesses aiming to enhance production efficiency while simultaneously protecting their profit margins. According to a report by Smithers Pira, the UV printing market is projected to grow to $9.58 billion by 2024, driven largely by advances in technology that bolster versatility and reduce operational costs. By integrating multiple functions—such as printing, curing, and cutting—into a single machine, businesses can streamline their processes, minimize labor costs, and reduce the need for extensive equipment inventories, all of which contribute to better overall economic performance.

Furthermore, the cost-benefit analysis shows that multifunctional UV printers can lead to significant savings in material usage. A study from the Printing Industries of America highlighted that digital printing solutions generally result in a waste reduction of up to 30% compared to traditional methods. This not only translates to direct savings on consumables but also positions businesses to respond more rapidly to market demands without incurring the high costs usually associated with conventional print runs. As companies leverage these printers, they can expect improvements in turnaround times and enhanced flexibility, further augmenting their profit margins and fostering sustainable growth in highly competitive markets.

In today's fast-paced production environments, leveraging the automation features in multifunctional UV printers is essential for maximizing productivity. These advanced printers not only deliver high-quality prints but also come equipped with automated settings that can significantly reduce manual intervention, allowing operators to focus on other critical tasks. Features such as automatic media sensing, job queuing, and remote monitoring streamline workflows and enhance efficiency throughout the printing process.

In today's fast-paced production environments, leveraging the automation features in multifunctional UV printers is essential for maximizing productivity. These advanced printers not only deliver high-quality prints but also come equipped with automated settings that can significantly reduce manual intervention, allowing operators to focus on other critical tasks. Features such as automatic media sensing, job queuing, and remote monitoring streamline workflows and enhance efficiency throughout the printing process.

Tip: Take advantage of pre-set profiles for different materials and projects. This will help in reducing setup times and ensuring consistency across different jobs. By configuring your UV printer with these profiles, you can quickly adapt to various production needs, minimizing delays and optimizing output.

Moreover, integrating UV printers with your existing automation systems can provide real-time data and insights, aiding better decision-making. Tip: Use software tools that allow for remote control of printing jobs. This not only helps in tracking the progress but also facilitates immediate adjustments when necessary, further maintaining the flow of production and reducing downtime. By incorporating these automation features, businesses can achieve higher production efficiency and meet increasing market demands effectively.