Inquiry

Form loading...

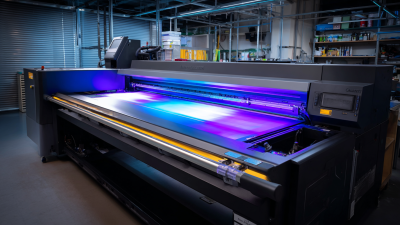

In recent years, the manufacturing landscape has undergone a significant transformation, largely driven by the advent of advanced technologies. Among these, the Industrial UV Printer stands out as a game-changer, unlocking new possibilities across various sectors. This innovative printing solution utilizes ultraviolet light to cure inks instantly, enabling vibrant, durable prints on an array of materials, including metals, glass, and plastics. As industries strive to enhance efficiency, reduce waste, and meet the growing demand for customization, Industrial UV Printers are at the forefront of this revolution. By offering unparalleled speed, quality, and versatility, they are not just transforming traditional printing methods but also paving the way for sustainable manufacturing practices. In this exploration of the future of printing, we will delve into the multifaceted benefits and applications of Industrial UV Printers, uncovering how they are shaping the manufacturing world for years to come.

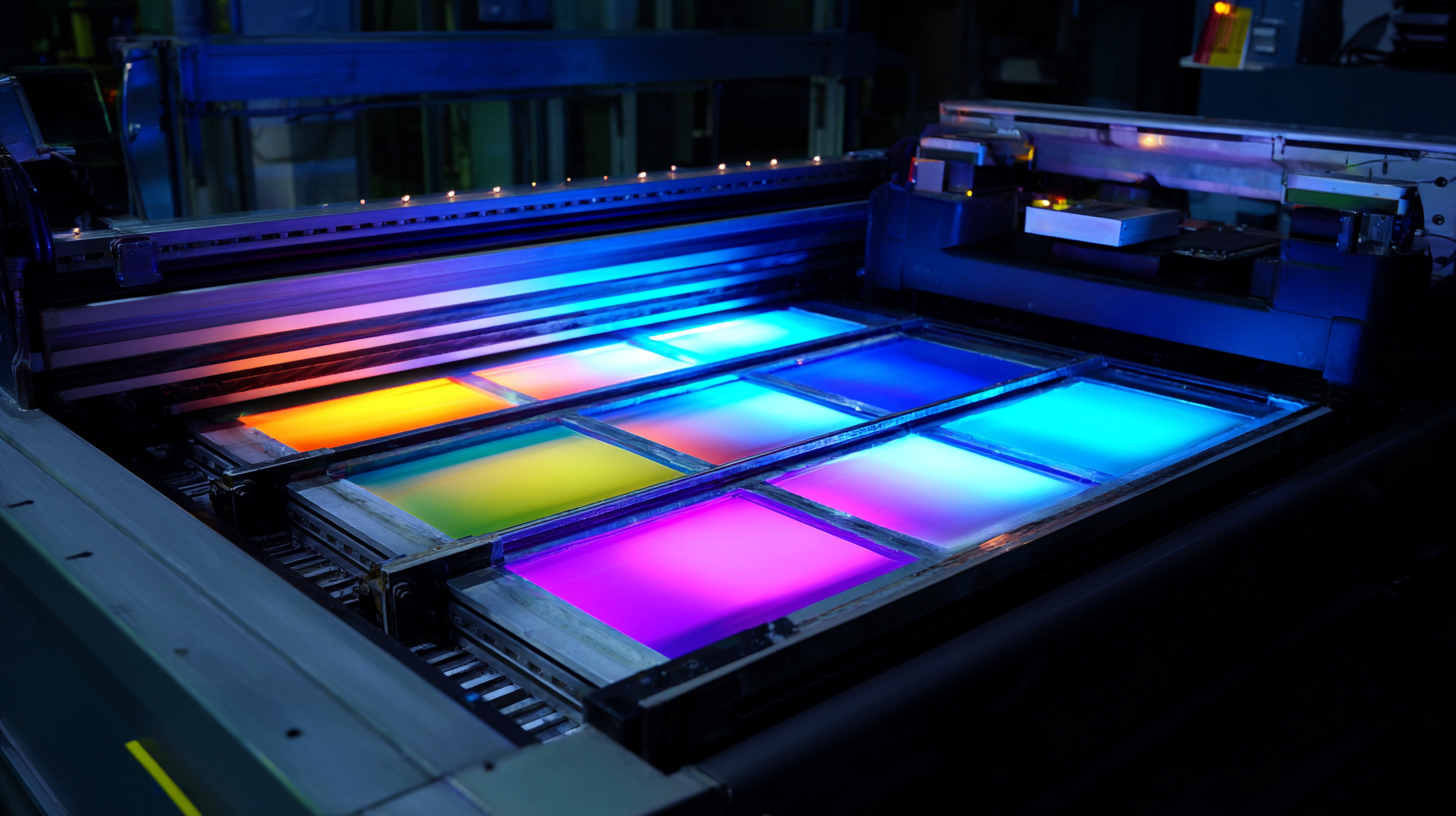

Industrial UV printing technology is rapidly transforming the manufacturing landscape by offering unmatched speed, versatility, and precision. Utilizing ultraviolet light to cure or dry the ink as it is printed, this method allows for immediate handling of printed materials without the risk of smudging or damage. The technology supports a range of substrates, from traditional paper to durable plastics, metal, and glass, making it suitable for various applications in industries such as packaging, signage, and interior design.

**Tip:** When considering industrial UV printers, it's essential to evaluate the range of materials they can handle. This flexibility can significantly enhance production capabilities and open new avenues for innovative product designs.

Furthermore, the environmental impact of UV printing is notably lower than that of traditional printing methods. The inks used are typically free from hazardous solvents and can contribute to a cleaner production process. As manufacturers become more eco-conscious, adopting UV technology not only supports sustainability goals but also aligns with consumer demand for greener products.

**Tip:** Always inquire about the energy efficiency of UV printers, as modern machines are designed to consume less electricity while delivering high-quality results, thereby reducing operational costs in the long run.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Fast Drying | UV printing utilizes ultraviolet light to cure or dry the ink as it is printed. | Increased production speed and efficiency. | Packaging, signage, and promotional products. |

| Versatility | Can print on a variety of substrates including plastic, wood, glass, and metal. | More options for product customization. | Decorative items, industrial components, and custom goods. |

| High Quality | Produces vibrant colors and sharp images with high resolution. | Improved customer satisfaction and product appeal. | Art prints, photography, and signage. |

| Eco-friendly Inks | UV inks are typically free of volatile organic compounds (VOCs). | Safer for the environment and workers. | Sustainable packaging and eco-friendly products. |

| Cost Efficiency | Eliminates the need for drying time, reducing labor costs. | Lower overall production costs. | Mass production and rapid prototyping. |

Industrial UV printing is transforming manufacturing processes by offering distinct advantages that optimize productivity and efficiency. The application of UV printing technology facilitates instant curing of inks, significantly reducing turnaround times compared to traditional methods. This is particularly beneficial in industries like packaging and label manufacturing, where speed and customization are critical. Reports indicate that UV printing can enhance operational efficiency by as much as 30% due to its rapid drying capabilities and compatibility with various substrates.

Moreover, the environmental advantages of UV printing cannot be overlooked. Traditional printing methods often rely on solvents that contribute to volatile organic compounds (VOCs), whereas UV-curable inks emit negligible VOCs, aligning with stringent environmental regulations. The adoption of LED curing technology further exemplifies the sustainability of UV printing, as it consumes less energy and produces less heat, thus prolonging equipment lifespan and minimizing maintenance costs. With the efficiency and eco-friendliness of UV printing, manufacturers are positioning themselves to meet the challenges of a rapidly evolving market landscape while also fulfilling the growing demand for more sustainable production practices.

The industrial printing landscape is undergoing a significant transformation, primarily due to the advent of UV printing technology. Industries such as packaging, textiles, and signage are experiencing the most profound impacts. In particular, the synthetic paper market is projected to reach USD 1,286 million by 2027, highlighting a growing demand for innovative printing solutions that can cater to diverse applications while offering durability and superior print quality.

Events like the FTA FORUM INFOFLEX are pivotal in shaping the future of label and package printing. Held in Pittsburgh, PA, this gathering underscores the industry's collective efforts to harness advanced technologies, such as industrial UV printers, which are not only efficient but also environmentally friendly. While these advancements promise enhanced production capabilities, the industry is concurrently facing challenges, most notably labor shortages. With only 8,700 trainees currently engaged in the printing sector in Germany, the lack of skilled labor is putting increasing pressure on manufacturers to adapt quickly and innovate continuously to meet market demands.

The integration of industrial UV printers into manufacturing processes is becoming increasingly vital, as companies strive for efficiency and sustainability. According to the Smithers Pira report, the UV printing market is projected to grow at a CAGR of 6.7% from 2021 to 2026, owing to advancements in ink technology and the growing demand for high-quality printing solutions. Implementing UV printers requires careful planning and proficiency to ensure a smooth transition. Best practices include conducting comprehensive training sessions for operators, which can significantly reduce error rates and enhance productivity. A study by the Printing Industries of America also suggests that companies that invest in thorough staff training experience a 20% decrease in production downtime.

Moreover, seamless integration of UV printers into existing workflows can be achieved by evaluating and upgrading pre-press and post-press systems to accommodate the unique requirements of UV technology. Regular maintenance schedules and a clear understanding of the environmental benefits of UV printing, which often uses fewer volatile organic compounds, can enhance overall operational efficiency. By adhering to these best practices, manufacturers can unlock the potential of industrial UV printers, ensuring they remain competitive in an evolving market landscape.

The evolution of industrial UV printing is significantly reshaping the manufacturing landscape, driving innovations that enhance efficiency and sustainability. Recent reports from various industry analysis sources indicate that the global market for UV printing is projected to grow at a compound annual growth rate (CAGR) of over 10% through 2025. This growth is fueled by advancements in technology that allow for faster production times and higher quality prints, appealing to industries ranging from textiles to packaging.

Moreover, emerging trends highlight the integration of artificial intelligence and automation in UV printing processes. These innovations not only streamline workflows but also reduce waste, addressing sustainability challenges faced by manufacturers. Notably, the textile manufacturing sector, valued at approximately $1.8 trillion, is experiencing a surge in demand for customized and sustainable printing solutions, further validating the pivotal role UV printers play in modern production strategies. As companies prepare for key industry events like the 2024 CXPE, unveiling new technologies and strategies, the future of UV printing looks promising, poised to redefine manufacturing norms across various sectors.