Inquiry

Form loading...

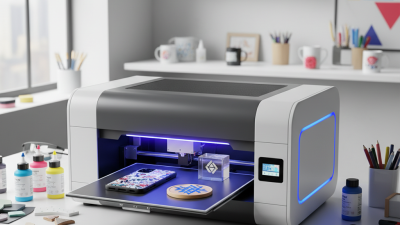

In recent years, the demand for high-quality printing has surged. A Home UV Printer has emerged as a popular solution for many households and small businesses. Industry expert John Smith, a leading figure in the digital printing arena, states, "Home UV Printers offer versatility and quality that traditional printers can't match." This highlights the growing appeal of these devices.

Home UV Printers can print on various materials, making them highly adaptable. Imagine printing vibrant images on wood, glass, or metal right from your home. While these printers are convenient, they can also come with a steep learning curve. Users may struggle with setup and maintenance initially. However, the stunning results often make the effort worthwhile.

It is essential to reflect on your printing needs before investing in a Home UV Printer. Consider the types of projects you plan to undertake. Will the printer serve personal crafts or professional purposes? Understanding your priorities can guide your decision. Investing in technology should be a thoughtful choice, not a quick one.

Home UV printers are revolutionizing the printing world. But what are they, and how do they work? These printers use UV light to cure or dry ink as it is printed. This process allows for vibrant colors and sharp details on various materials. Reports indicate that the demand for UV printing is expected to grow by over 15% annually through 2025. This should prompt many to consider these printers for their home projects.

When selecting a home UV printer, consider the materials you'll print on. These printers can work with wood, metal, glass, and acrylic. This versatility is notable but may require some experimentation. Not all inks adhere well to every surface. It’s essential to test before committing to a large project.

**Tip:** Always keep the printer clean. Ink can clog the nozzles if not maintained properly. Regular cleaning preserves print quality. Another important point is to manage the exposure to UV light. Overexposure can harm surfaces or cause printed material to fade over time. Take your time to learn and adapt as you go; mastering this technology takes practice.

| Feature | Description | Benefits |

|---|---|---|

| Print Type | UV printing uses ultraviolet light to dry or cure ink as it is printed. | Provides instant drying and glossy finishes. |

| Media Flexibility | Can print on a variety of materials including plastic, wood, metal, and glass. | Supports diverse printing projects and creativity. |

| Durability | UV ink is resistant to scratches, fading, and water. | Long-lasting prints suitable for indoor and outdoor use. |

| Print Quality | High resolution and vibrant colors. | Produces professional-quality results for any project. |

| Cost-Effectiveness | Initial investment is higher, but lower ink costs over time. | Offers savings on large volume projects. |

Home UV printers offer unique advantages for various materials, making them a great choice for printing needs. They excel in versatility. They can print on wood, plastic, glass, and even metals. This capability allows users to experiment with countless projects. According to a recent industry report, the global UV printer market is projected to grow at a CAGR of 7.5% from 2022 to 2030. This growth reflects the rising demand for customized solutions.

The quality of prints produced by home UV printers is another critical benefit. The UV curing process ensures vibrant colors and sharp details. Prints resist fading and scratches, making them ideal for durable items. In fact, studies show that UV prints have a lifespan that is 20-30% longer than traditional inks. However, this technology is not without its challenges. The initial cost can be high, which may deter some users. Additionally, mastering the printer settings requires time and patience.

Another key advantage is the quick drying time. UV inks dry instantly under UV light. This feature significantly reduces production times. Users can move from one project to another without long wait times. Still, it’s important to ensure safety when operating UV printers. Adequate ventilation is necessary to avoid fumes. Users should also be cautious with UV exposure. Balancing these factors can improve both the experience and the outcome.

Home UV printers stand out when compared to traditional printing methods. They offer greater versatility in the types of materials you can print on. You can print on wood, metal, or even glass. Traditional methods often limit you to paper. This opens up new avenues for creativity.

Print quality is another significant factor. Home UV printers provide vibrant colors and sharp details. The ink is cured instantly, which minimizes the risk of smudging. With traditional techniques, some options don’t dry quickly, leading to imperfections. However, achieving the perfect print with a UV printer can be tricky. It requires careful calibration and sometimes practice is needed.

Tips: Choose the right media for your prints. It can make or break the final product. Experiment with different settings to find what works best for you. Don’t hesitate to make mistakes – learning is part of the process. Embrace the challenges of UV printing. Each error can guide you to better outcomes in the future.

Home UV printers offer a unique avenue for creativity across various projects. Their ability to print on different surfaces expands possibilities. You can use them for materials like wood, glass, metal, or plastic. This versatility attracts artists and makers alike. Dreamcatchers, photo frames, and custom gifts all benefit from UV printing. The vibrant colors and intricate designs draw attention.

In professional settings, UV printers enhance branding efforts. Businesses utilize them for promotional materials and signage. Unique designs can differentiate products in a crowded market. However, some may struggle with technical aspects or initial costs. Mastering the printer takes time and experimentation. Mistakes can lead to wasted materials. Finding the right settings often requires trial and error, but persistence pays off.

Home UV printers are also valuable in niche crafts. DIY enthusiasts use them for home decor projects. Customized tiles or artistic coasters are just a few ideas. The satisfaction of creating something personal is unmatched. Yet, the learning curve can be steep. Exploring different materials and designs means facing setbacks. Embracing imperfections can spark creativity and innovation.

When choosing the right home UV printer, several factors should come into play. First, consider the print size. Some printers handle larger materials better. A small device may not support larger projects. Think about your workspace. An oversized printer may cramp your area. Measurements matter.

Another key factor is print quality. UV printers often offer clear, vibrant colors. But this can vary between models. Investigate print resolutions before deciding. Look for reviews from users. Their experiences can provide valuable insights.

Lastly, think about the cost. Not just the purchase price, but ongoing expenses matter. UV inks can be pricey. Some printers may require more maintenance than others. Balancing quality with affordability is essential. Evaluate how you will use the printer over time. Reflect on what you truly need from this device.